Componenty Overhauls

For Heavy Equipment

We offer a range of exchanges, rebuilds and repairs to best fit with your situation.

Overhaul Capabilities

Balance uptime and price considerations

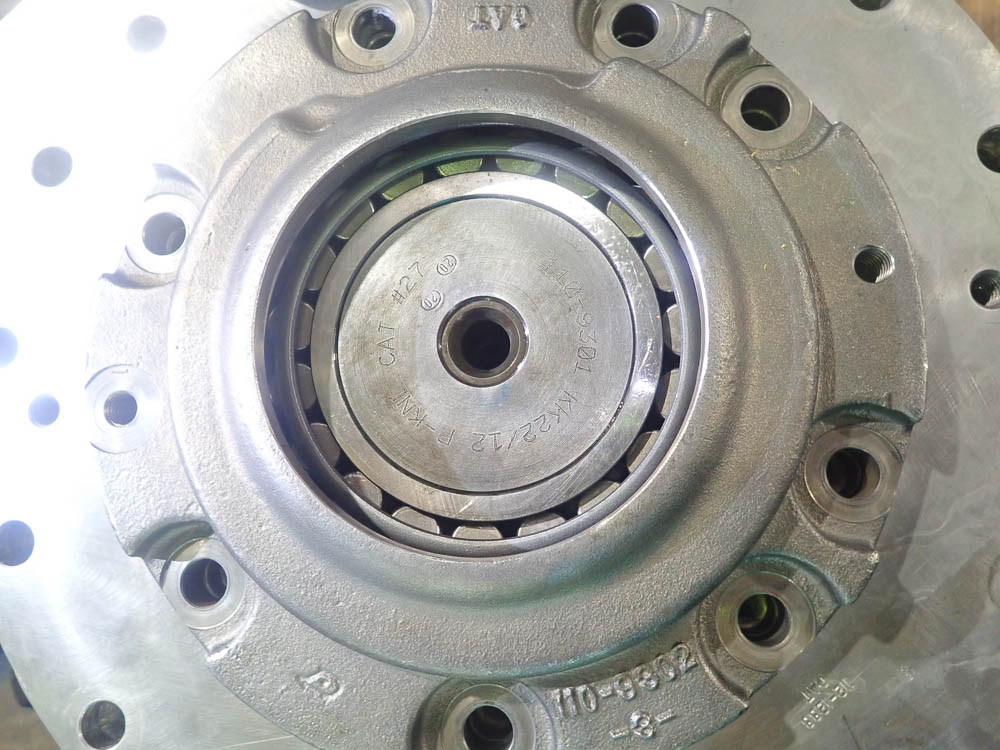

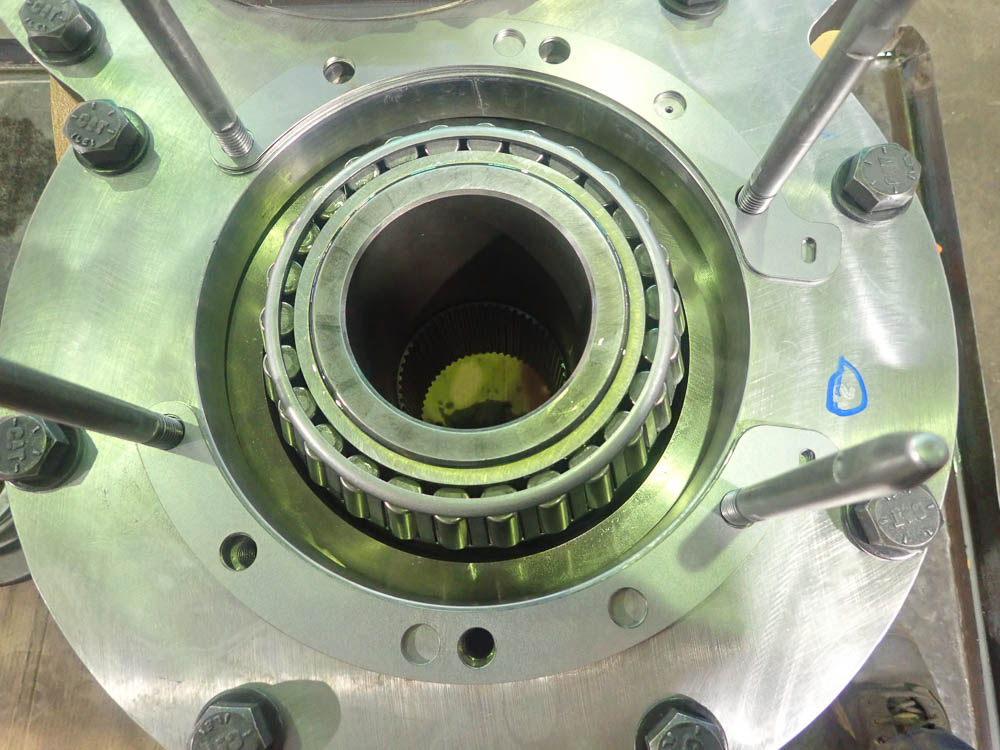

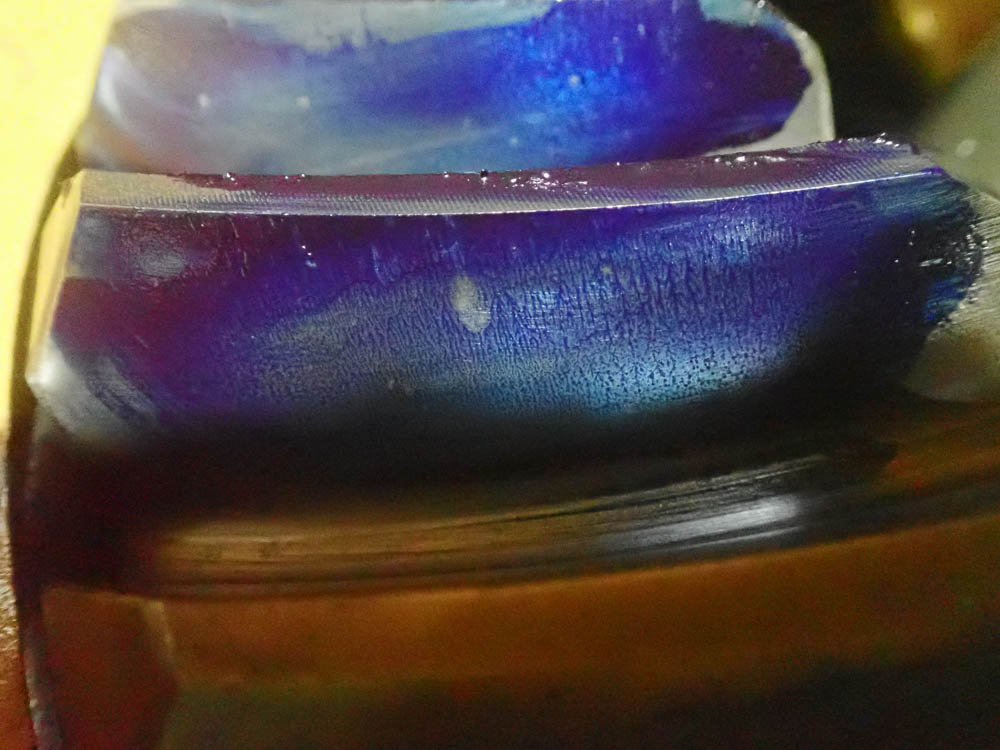

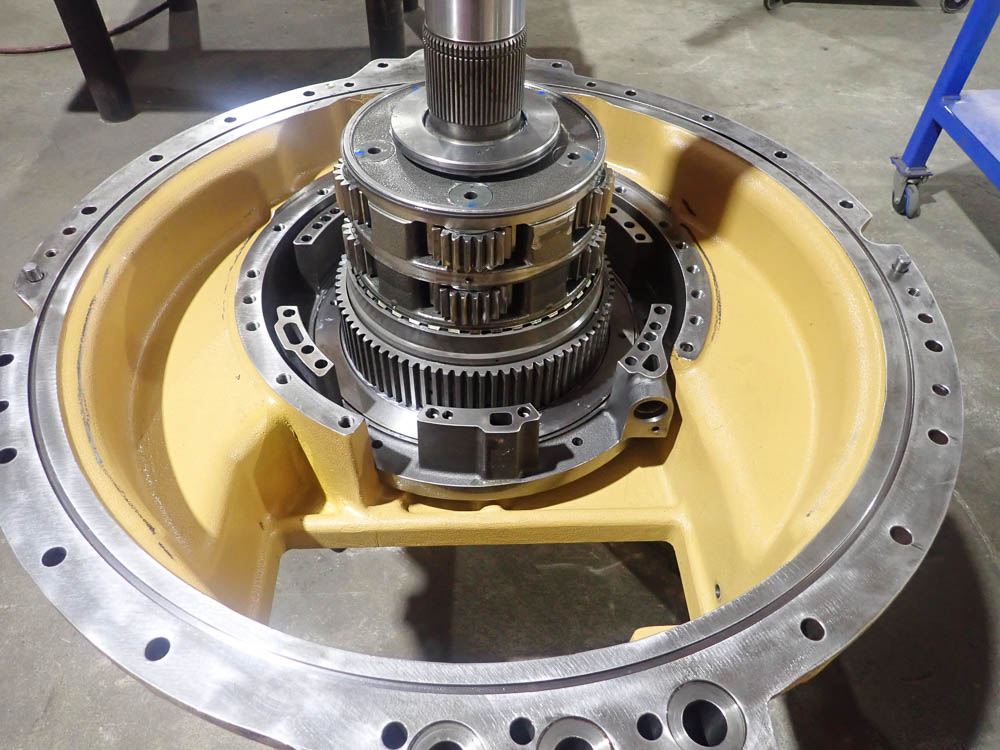

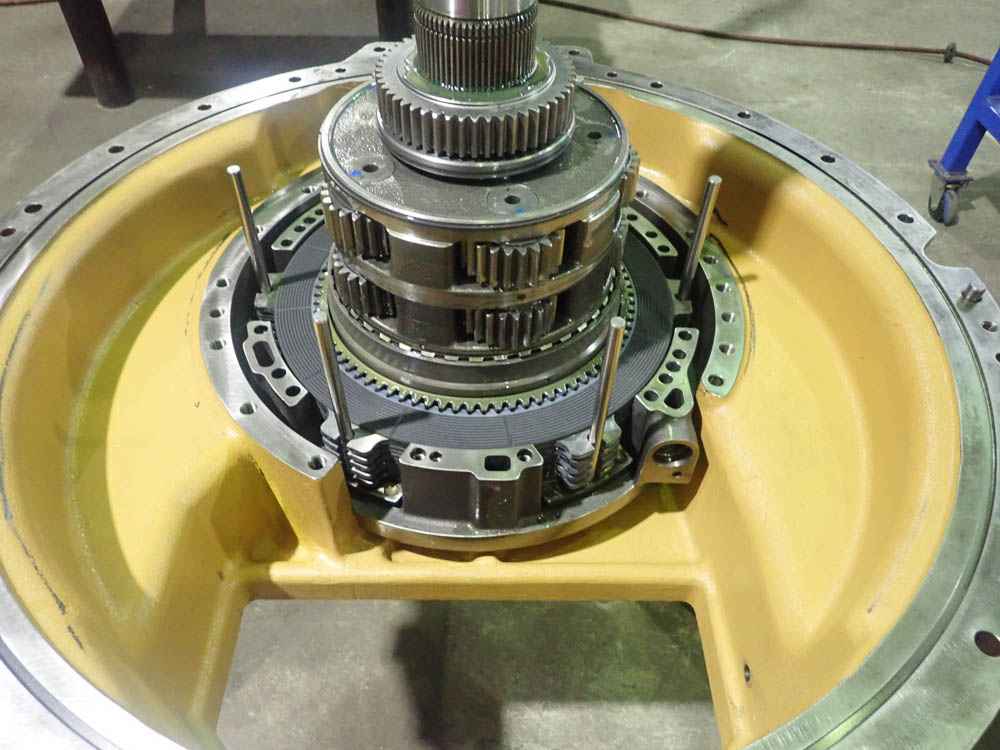

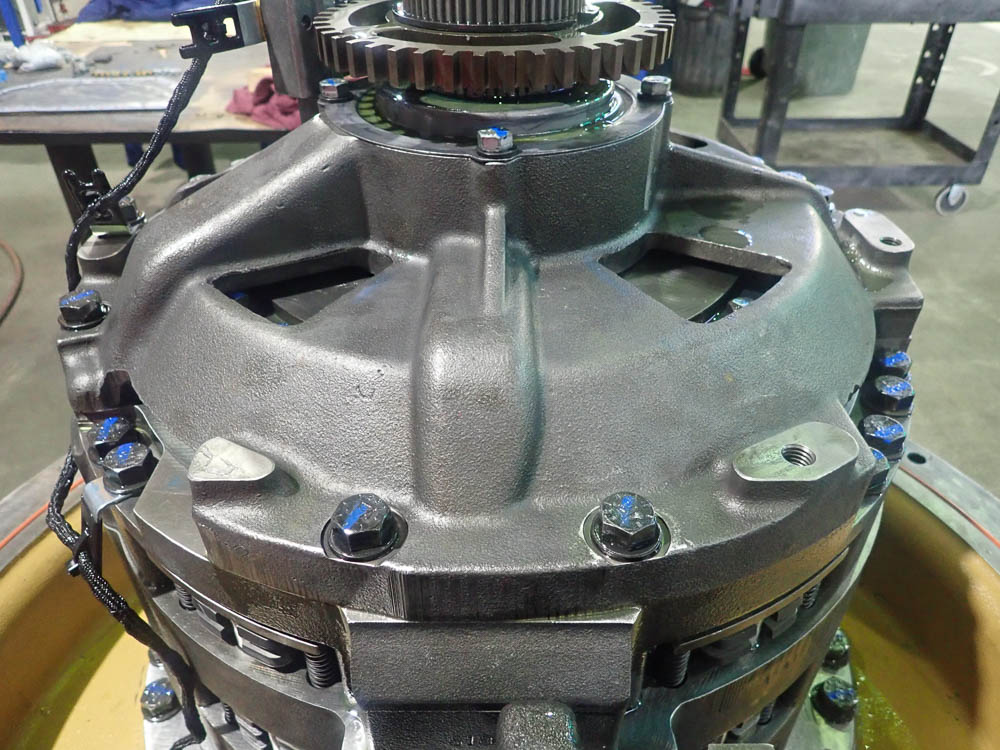

Component Works have a stringent quality assurance procedure and follow OEM reusability guidelines. We only utilise OEM parts, unless otherwise requested from the customer and all reclamation works outsourced to our suppliers is QA’d and measured before being reassembled.

Heavy equipment overhauls can have the parts replaced with refurbished parts, or can be rebuilt to manufacturer as new specifications. Or preventative maintenance can be performed on a schedule.

Exchange

Shortest Downtime

Eco-friendly Option

12 Months Warranty

- Peace of Mind “As New” 90%

- Price 65-85% of new 75%

- Turnaround 90%

Rebuild

Known Component History

Upgrades

12 Months Warranty

Retain Own Iron

- Peace of Mind “As New” 90%

- Price 50-65% of new 60%

- Turnaround 75%

Repair

Extended Life

Parts Re-use

New Parts Warranty

- Peace of Mind Repair 90%

- Price 25-50% of new 35%

- Flexible Turnaround 50%

Options for Componenty Overhauls

Exchange Parts

This option offers the least downtime. We swap components with a refurbished part from the shelf. Overhaul exchange comes with 12 months warranty.

- Fastest

- Less waste

- Save 15-35% off new parts price

Rebuild Parts

- Keep your own iron

- Upgrades available

- Save 35-50% off new parts price

Repair Parts

- Scheduled

- Re-use your own parts

- New part warranty

- Save 50-75% off new parts price

All fully tested and certified

MAKAY’S OWN

Component Overhauling

Specialists

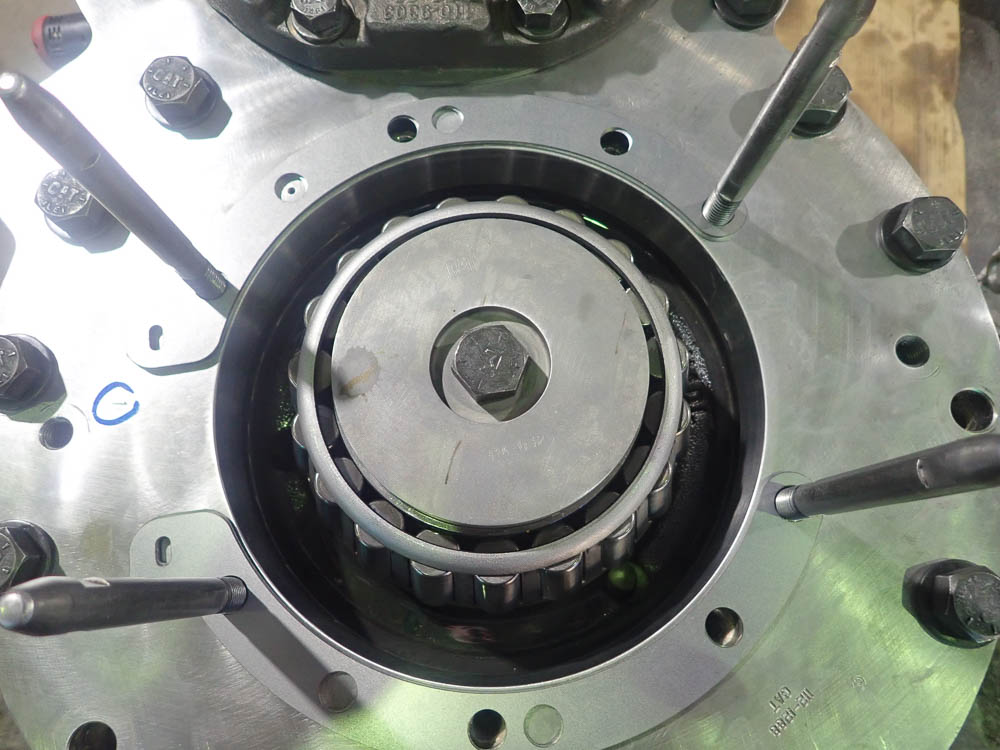

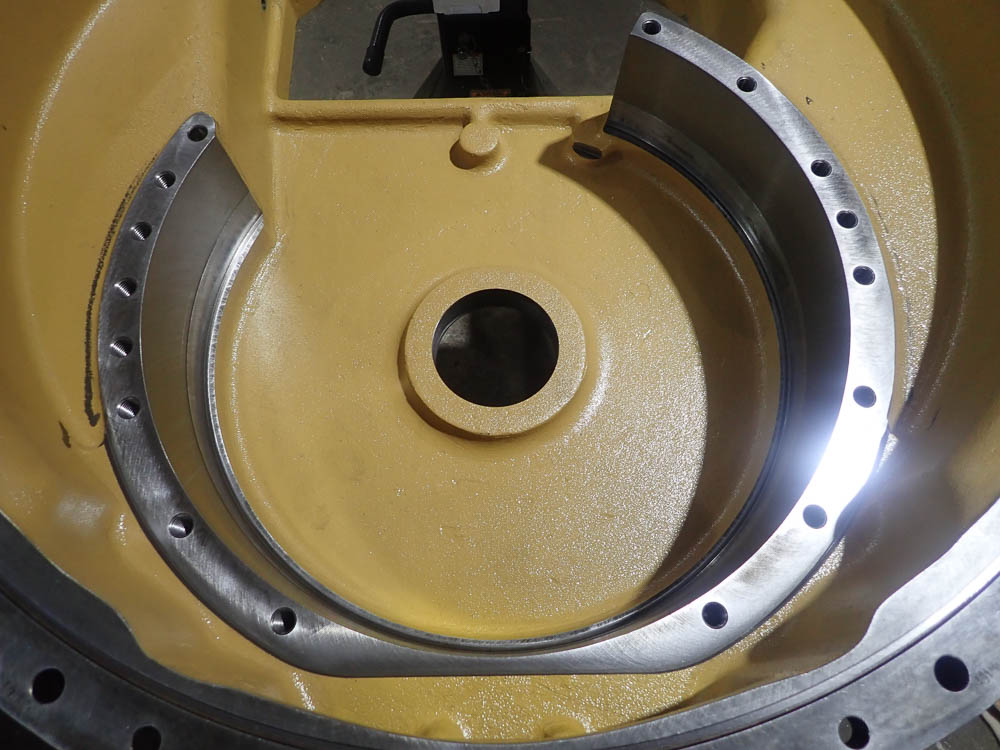

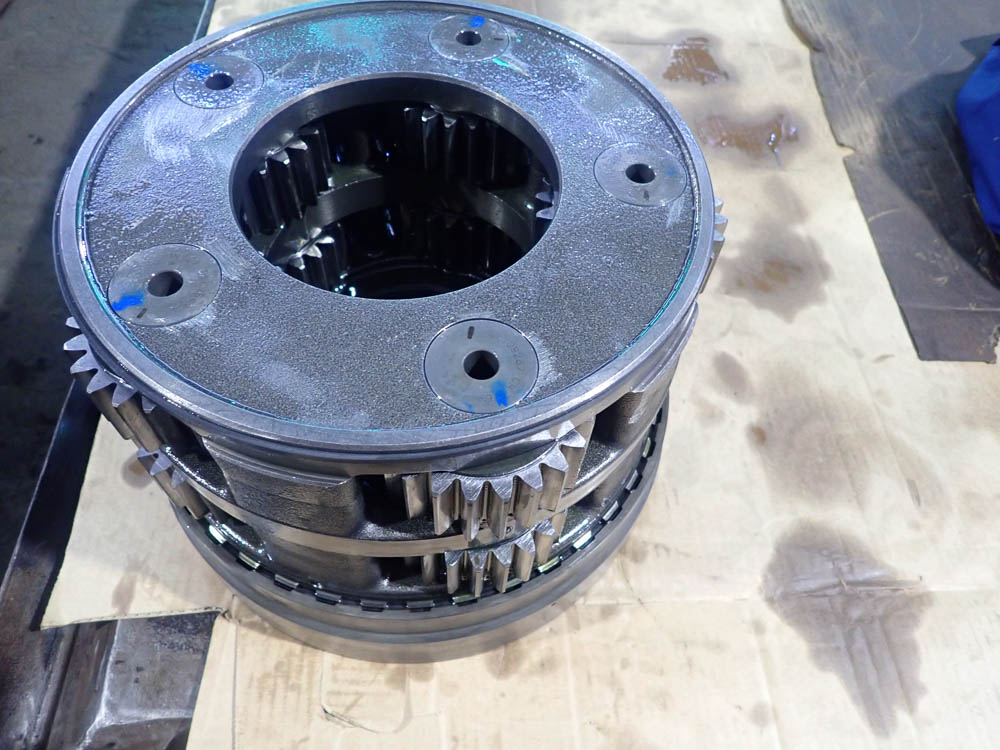

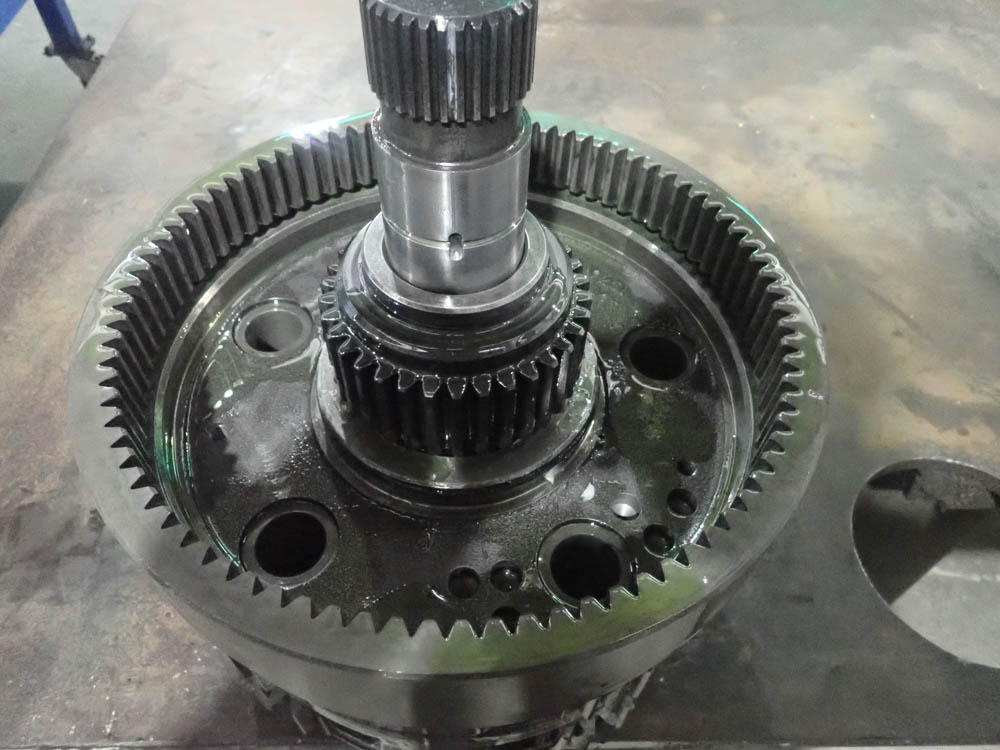

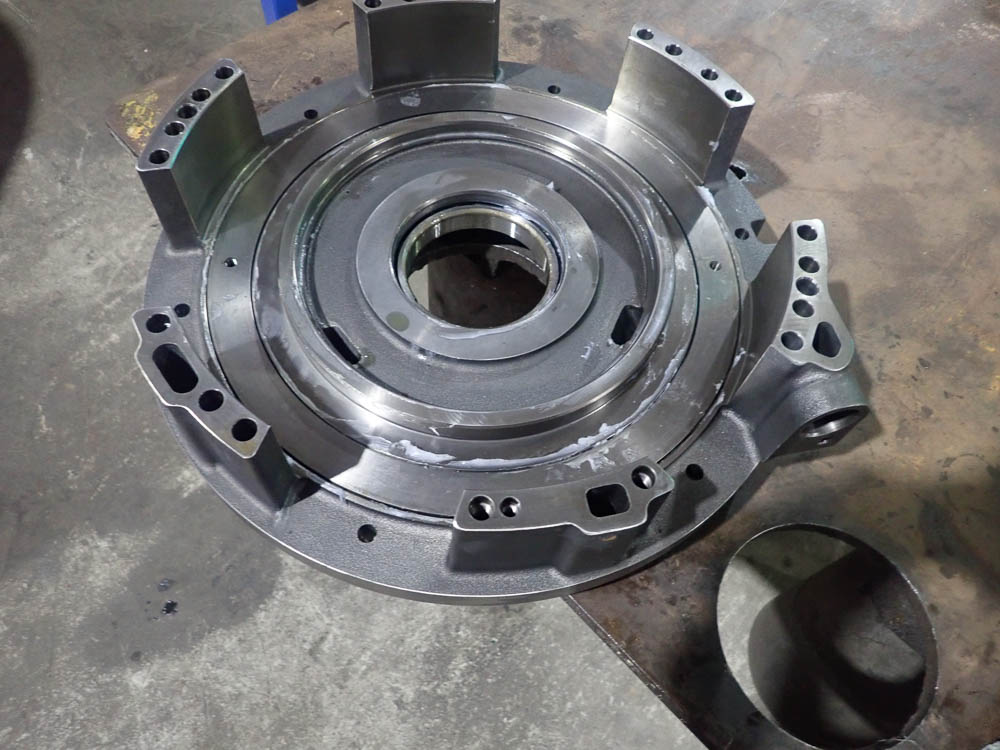

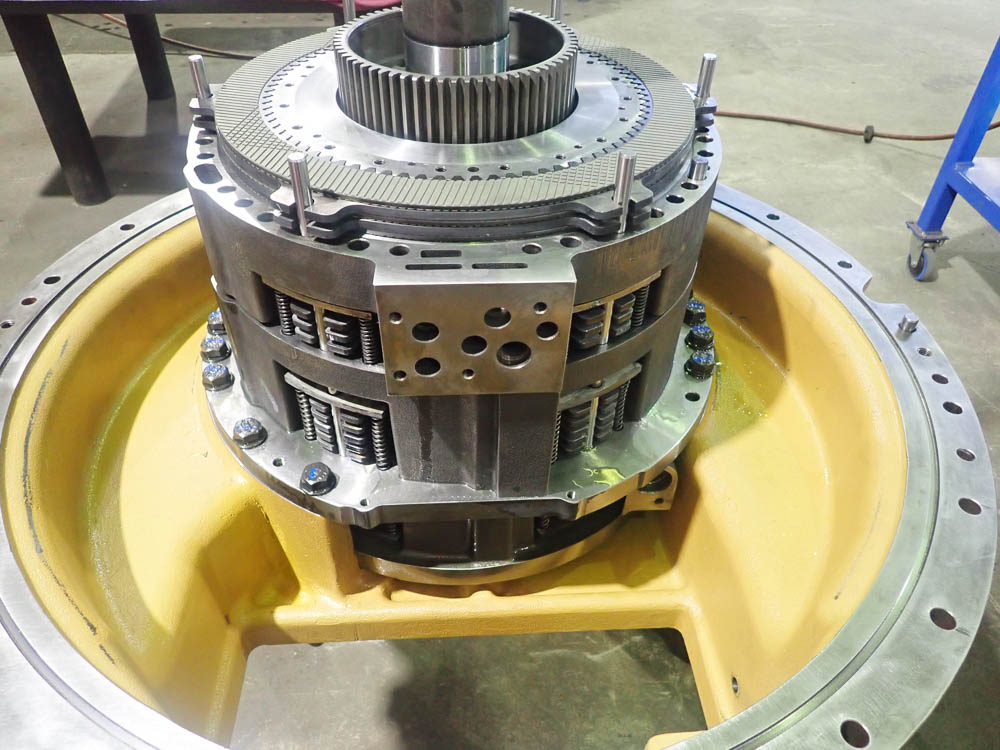

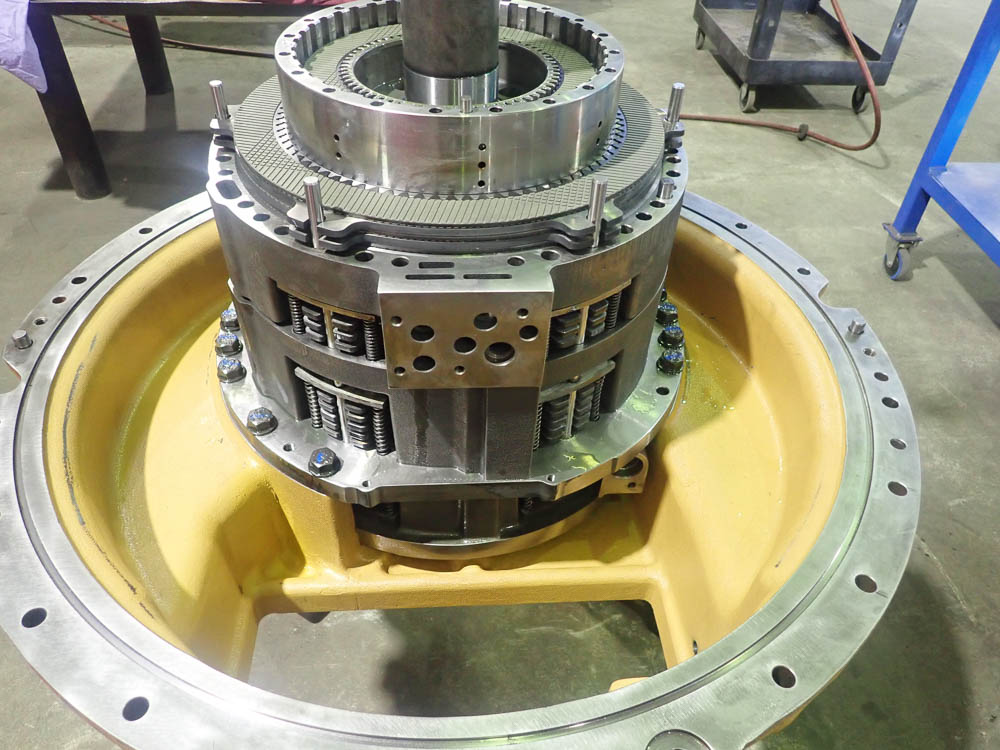

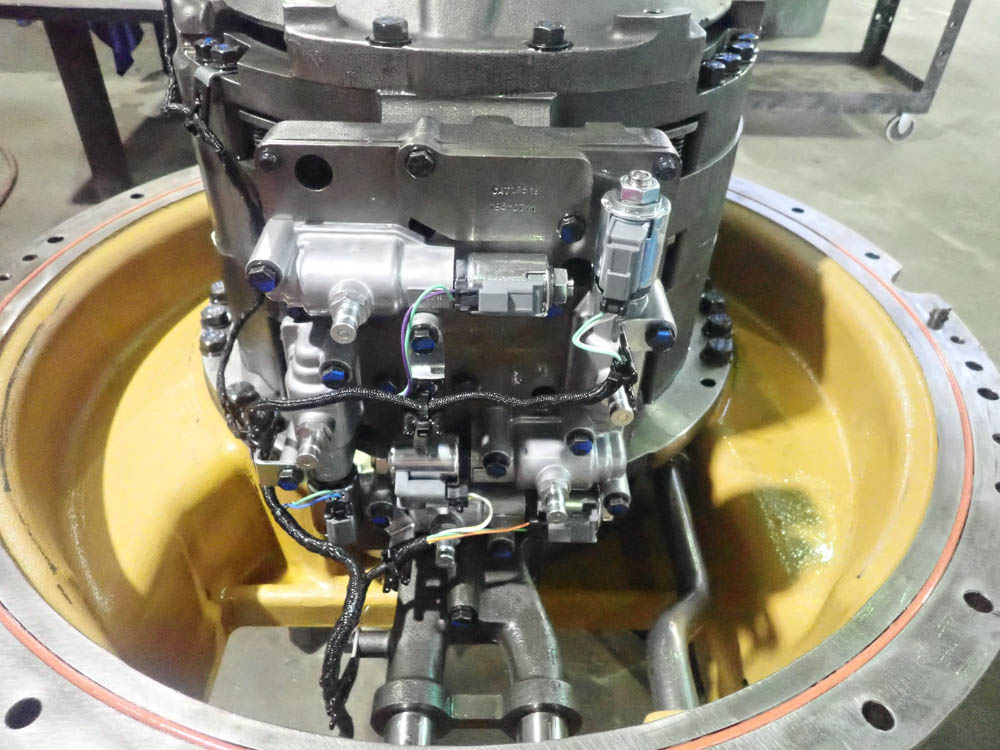

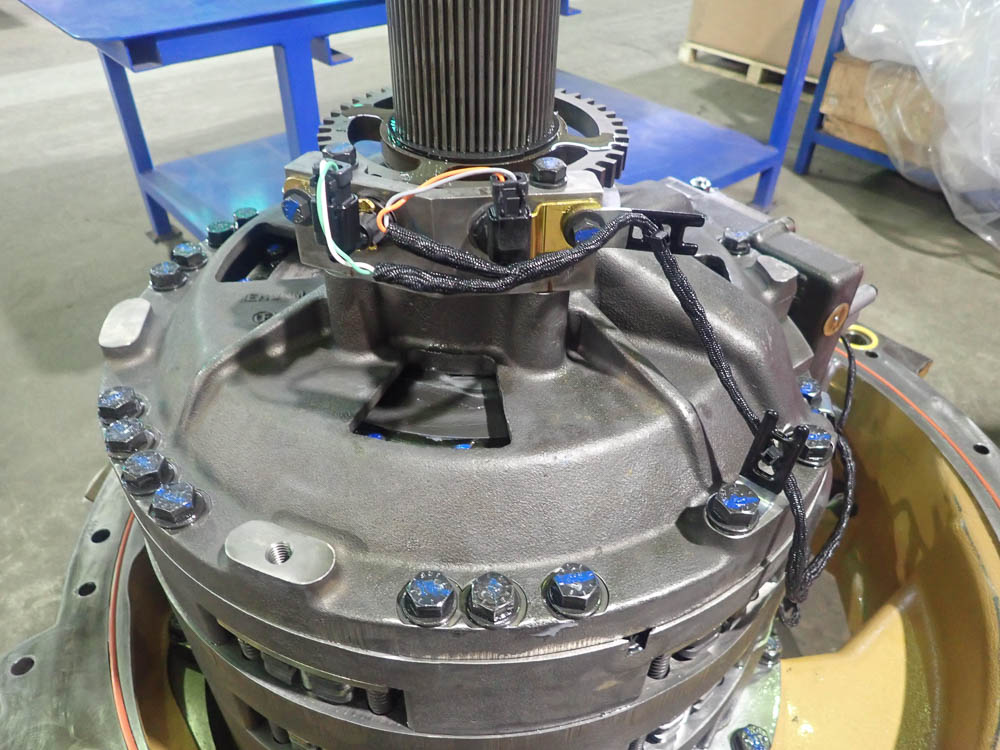

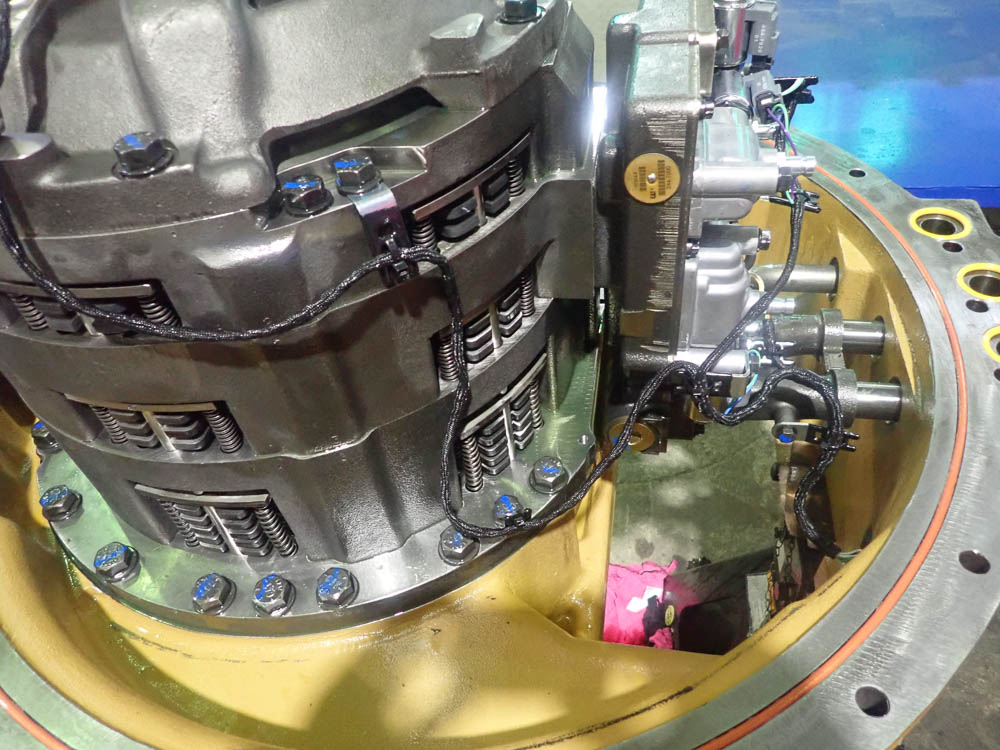

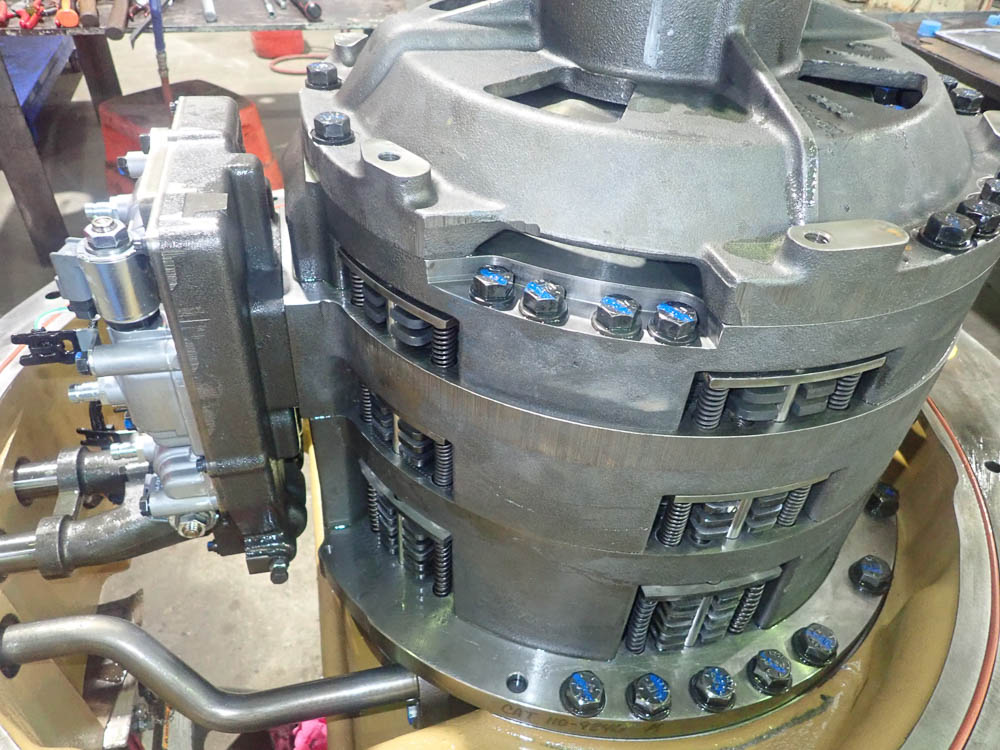

Power train specialists

(torque converters & transmissions)

Equipment we

Overhaul

Torque Converters

Transmissions

Diesel Engines

Front & Rear Suspension

Hydraulic Valving & Pumps

Hydraulic Cylinders

Track Frames

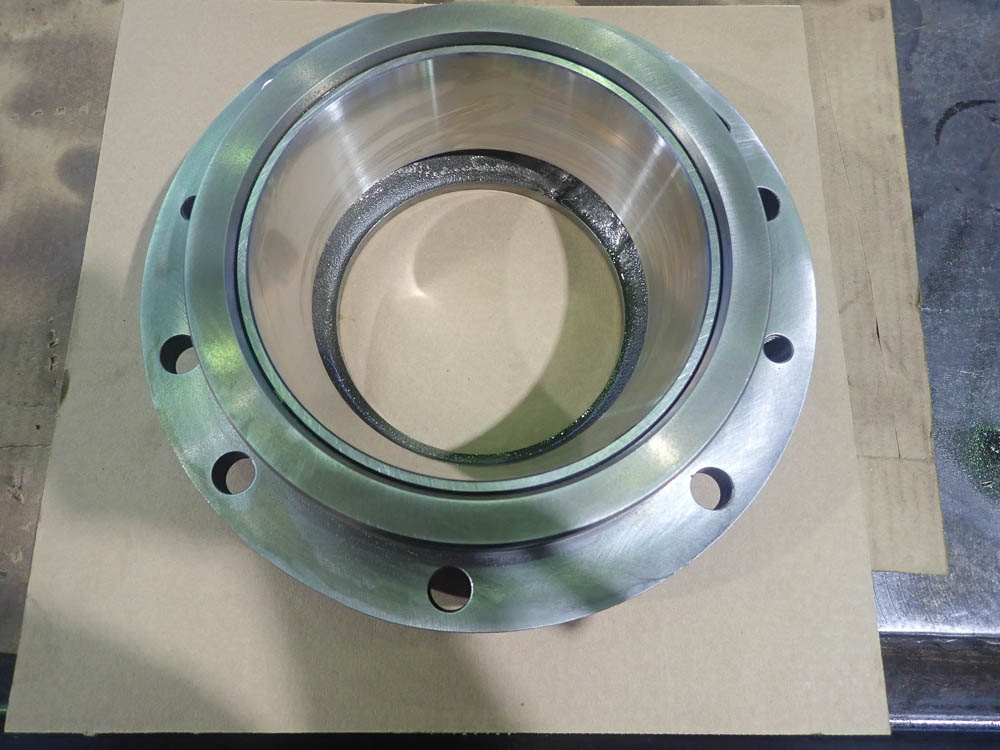

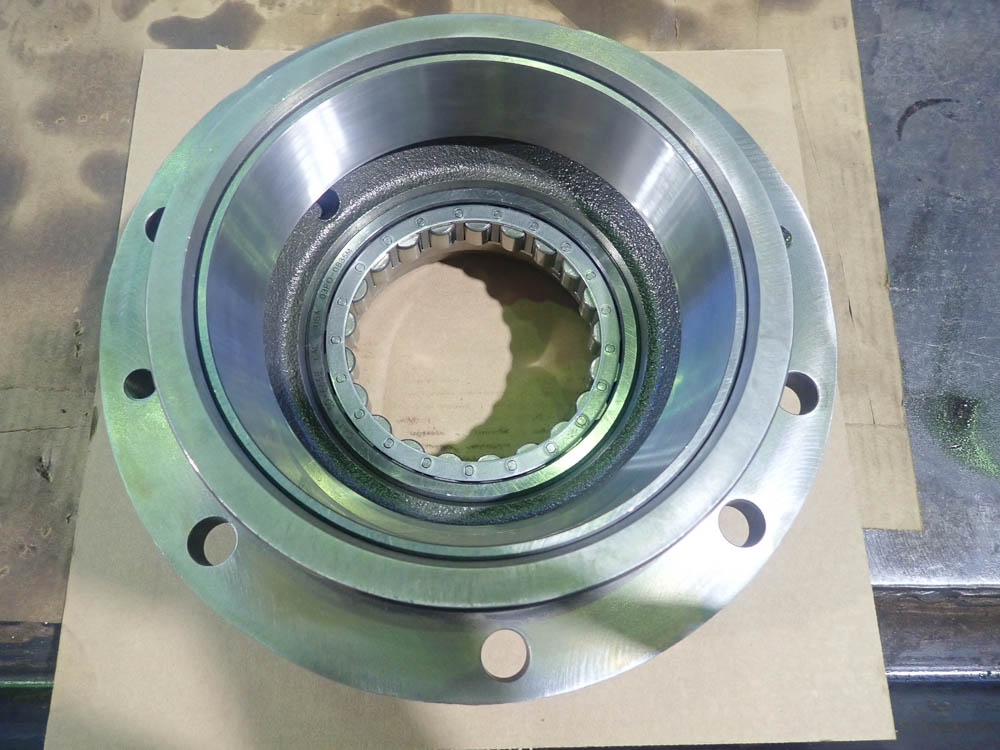

Final Drives

Brake Groups

Radiators

Differentials

Operator Stations

Steering

Attachments

Download our Capability Statement

Read more about the work we are proud to be a part of.

ABOUT COMPONENT WORKS

Mackay’s Heavy machinery Repairs, Servicing & Parts

Component Works have alternative solutions for all your heavy machinery and fixed plant needs. We have a rigorous Quality Assurance system and safety procedures. This makes us a preferred employer and a valued partner to operators in the Mining, Civil, Construction and Agricultual industries.